Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

Item NO.:

SY-2621Color:

Steel Blue or CustomizedLead Time:

20 daysWarranty:

1 YearSize Range:

customizedProcessing Range:

flat glass

Performance and working principle of equipment

Mainly used for automatic glass loading and transmission, the back can be connected to glass cutting machine, glass edging machine, glass cleaning machine, glass hollow processing equipment and so on. When the glass is placed in the specified position, the sheet sucker is automatically turned up and placed on the transfer roller table after the glass is adsorbed, and the glass is automatically transported to the main machine of the cutting machine.

Note: the number of glass can be automatically controlled, that is, before cutting the number of cut glass, after the completion of the cutting manual operation on the loading machine can continue to take pieces, to avoid human factors to cut the glass.

Equipment Parameters

Flip sprocket chain: special high-precision reinforced type.

Transmission roller: imported pu material

Vacuum sucker: imported natural rubber material (double adsorption structure)

Transmission / flip motor: Bonnie motor

Vacuum pump: Wenling stone bridge vacuum pump

Bearing: Harbin, China.

Electrical components

PLC controller: Panasonic Japan

Frequency converter: Taiwan Delta

Optoelectronic switch: Shanghai SONON

Circuit breaker and motor protector: China CHNT

Control elemer: imported flexible shielded eleme

Contactor: Siyan technology

Main control vacuum solenoid valve pneumatic original: Zhejiang Yongqing manufacturing

Technical Parameter

Loading glass size range: minimum size: 1500*1200mm, maximum size: 2500*2100mm

Loading thickness 2-19mm

Fastest loading time 40s

Transport speed 0-40m/min (adjustable )

Maximum suction depth: 700mm

Maximum loading weight : 500KG

Number of loading arm on one side: 3 arms

Number of suckers on one arm :3 suckers

Flip side: single

Loading station: single

Voltage: 380V/50hz (could be customized)

Power: 12KW

Compressed air: 0.3~0.5Mpa

Vacuum pressure: -70 ~ 90 KPA (adjustable according to glass thickness)

X axis conventional walking speed: 25m / min (variable frequency adjustable)

Y-axis conventional walking speed: 5 m / min (variable frequency adjustable)

Technical description:

Walking -- Flip arm -- Automatic induction glass -- Sucker adsorbed glass -- The lifting of the sucker separates the glass from the rack -- Return to original -- Reverse arm reposition -- Conveying glass

Program settings: can automatically set the loading pieces and loading station order. The equipment carries on the movement automatically, the automatic takes the piece, the automatic conveys.

Position walking mode: it can automatically adjust zero position, automatically detect workstations, and automatically return to original position.

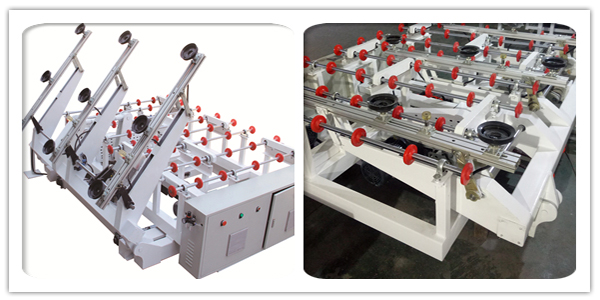

Related Pictures

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712