Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

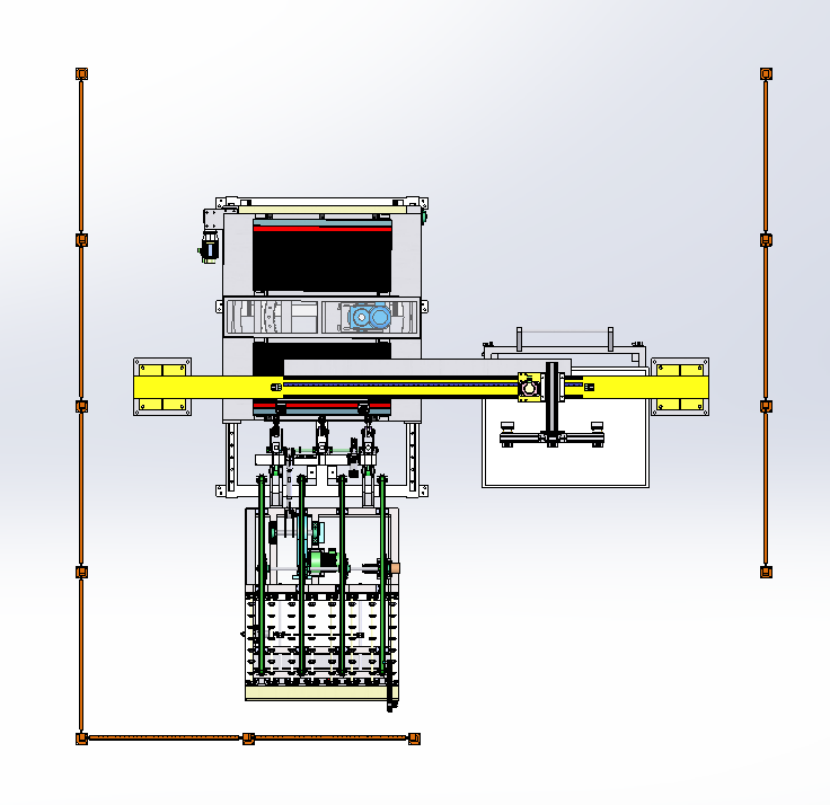

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

This line is designed according to the requirements of the buyer. It is used to complete the process of automatic flipping, loading and automatic paper placement of photovoltaic glass sheets.

Brand:

RuilongItem NO.:

CustzomiezdProduct Origin:

ChinaColor:

Steel Blue Or CustomizedShipping Port:

Shanghai orWarranty:

1 yearSize Range:

1 yearProcessing Range:

CustomizedProduction Line Composition:

· OP-1: Electric Control Box

· OP-2: Fence Opening

· OP-3: Rotating Material Rack (SY-1265A)

· OP-4: Cross-shaped Robotic Arm (SY-1265-1Z) with two waste paper carts

· OP-5: Rapid Glass Turner (SY-1265C)

Production Line Layout: A standard LAYOUT (STEP format) can be provided upon further design.

Standard Process Flow Overview:

1. Start the equipment and perform a no-load run to confirm that all parts are functioning well before starting production.

2. Use a forklift to place the required raw glass sheets and racks on our base, retaining removable fixing pins. If packaged in wooden boxes, they need to be disassembled in advance.

3. The raw glass sheets are grabbed by the suction cups of OP-3 and flipped to the horizontal plane, then transported to the exit position by belts and rubber wheels. The lower machine gives a signal to execute the flow or wait. During this interval, the suction cups can rise again to wait for the next flipping signal, improving the takt time.

4. OP-2 is responsible for removing the paper between the raw glass sheets during the flipping intervals by OP-3 and transferring them to the waste paper box.

5. OP-1 has an automatic side-changing function, and OP-2 is equipped with a paper pressing mechanism on top of the raw glass sheets to prevent the paper from being moved or falling off due to static electricity. The last piece of paper may need to be picked up manually.

6. When one side of the glass is depleted, the machine can be set to alarm and stop automatically, requiring manual intervention for side changing, or it can be set to automatically change sides in the program. After changing sides, an operator can reload a pack of glass or wait until both sides are completed before replenishing.

7. This completes the entire process flow of our equipment, achieving unmanned operation under standard process flow conditions. (For control system alarms, operators should immediately stop work upon receiving the alarm and troubleshoot the fault area and specific cause based on the alarm code.)

Key Equipment Parameters and Configurations: (Detailed descriptions for OP-1, OP-2, and OP-3 are omitted here for brevity but can be expanded similarly.)

|

No. |

Item |

Parameter Declaration |

Remark |

|

1 |

Glass Sheet Size |

1200*650mm |

If there is any change, please inform us in time. |

|

2 |

Glass Sheet Thickness |

2-5mm |

If there is any change, please inform us in time. |

|

3 |

Glass Type |

Photovoltaic Glass |

Coated on one side. |

|

4 |

Expected Full Line Beat |

20-25S/PCS |

The beat can be adjusted according to the actual situation. |

|

5 |

Back-end Process |

Conveyer |

If there is any change, please inform us in time. |

|

6 |

Voltage Type |

380V/50Hz |

Domestic use |

|

7 |

Line Elevation |

950±40mm |

Customize parameters as needed |

|

8 |

Utilization Rate |

≥98% |

Switch the calculation by 20 seconds |

|

9 |

Color |

RAL9003 (Painted) |

Glossiness 80%-90% |

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712