Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

This automatic ultra thin glass cutting machine is used for cutting ultra thin glass. Applicable to OLED glass, photoelectric glass, liquid crystal glass, display glass, mobile phone glass, touch screen glass, OGS process of ultra-thin glass cutting, high cutting efficiency, good accuracy, high yield, and easy to operate, the operator has no technical requirements.

Item NO.:

SY-1311Color:

Steel Blue or CustomizedLead Time:

25 daysWarranty:

1 YearSize Range:

10*10mm-1250*1050mmProcessing Range:

OLED glass, photoelectric glass, liquid crystal glass, display glass, mobile phone glass, touch screen glass

Basic performance:

1. Specification of equipment :

Maximum cutting size:1100*1400mm

Workbench height:900±30mm.

Equipment weight:1.5T.

Cutting thickness∶0.2~8mm

2.Cutting Parameters∶

Parallel straight line error:≤±0.08mm/m

Diagonal accuracy:≤±0.15mm/m

The speed of cutting bridge∶0~80m/min.(Adjustable)

The accelerated speed of cutting bridge≥3.0m/s²

The speed of chuck block≥80m/min

The accelerated speed of chuck block≥6.0m/s²

Cutter head positioning accuracy ≤±0.001 mm

Power:

Install power:380V/50HZ

Actual power:4KW。

Compressed air:0.6MPA.

Equipment characteristic

Equipment frame: The equipment is treated with aging to ensure that the table is free of deformation, and that the parallelism is accurate

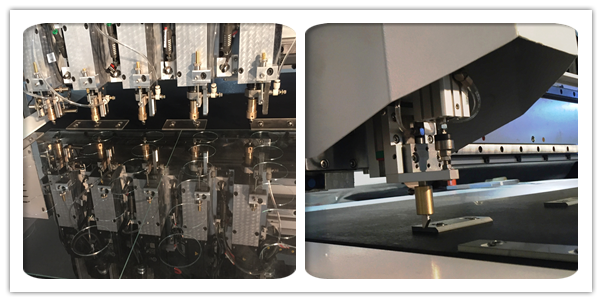

Cutter holder: the cutter head can be rotated 360 degrees. The upper and lower cutting can cut any straight line and all kinds of special-shaped glass

Table:0 grade Marble

Oil supply:Automatic pneumatic oiling, same time with down cutter, Dual oil control, kerosene and cutting oil can be used simultaneously. Conveyor: air flotation

Mechanical part

Guild rail:Taiwan, grinding grade. Taiwan Silver

Cutter wheel / wheel clamp: Japan, NIKKEN;

service life 3 - 50 thousand meters / handle (straight line)

Bearings: Japan NSK

Supply 3 cutters, the cutter details according to cutomers’glass thickness. Cutting thickness and cutter wheel matching suggestion:

Electrical part

Direct control using brand computers, Microsoft windows interface Voltage: 380V/50HZ. equipment, with variable pressure device

Motor: Japan Yaskawa servo motor.400、850 watts

Proximity switch: Import

Control card: American imports, Galil, the card has serial number, you can search online to identify its authenticity

Card function description, will be randomly distributed a tutorial material. The content is very large!

The main electric elements: AC contactor relay and Japan; Schneider of France.

Pneumatic proportional valve: Japan SMC

Software

Combination with the motion control software

Optimization software and production management software can be used in conjunction with the Internet

It has the function of down knife protection。

With automatically calculate capacity function

With more than two thousand kinds of cutting Gallery (can facilitate drawing and operation)

AUTOCAD Drawing software is compatible.

The optimized software is directly compatible with the cutting software It has automatic correction function to ensure cutting accuracy

Cutting path selection function to ensure optimum cutting speed

Automatic debugging cutting knife pressure, fast accurate and stable.

Cutting pressure automatically, can effectively guarantee the cutting effect quickly

The origin correction function. Can set origin second time.

Operation input: the keyboard and mouse. Chinese/English dialogue interface

With functions of cutting knife pressure automatic mediation, to ensure optimal cutting effect.

Special-shaped template scanning: with a variety of (including special-shaped) template for point by point scanning into CAD graphics function.

Anhui Ruilong Glass Machinery Co., Ltd. is a senior enterprise specializing in the production of CNC glass cutting lines and other glass machinery.Our company has advanced production technology and mature business model, and is your reliable partner.

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712