Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

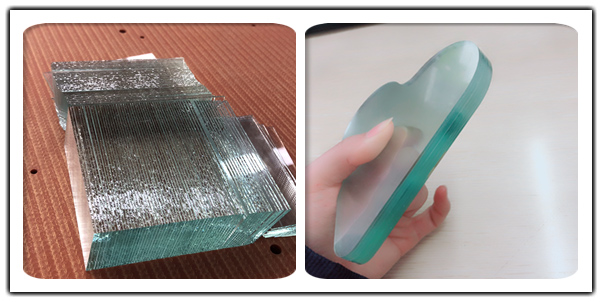

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

SY-8080 NC glass cutting machine could cut very small irregular glass. A popular machine for small factory and studio.

Item NO.:

SY-8080Color:

Steel Blue or CustomizedLead Time:

15 daysWarranty:

1 YearSize Range:

10*10-800*780mmProcessing Range:

Ornaments, mosaics, handicrafts, liquid crystal displays, optical glass and other Irregular glass

Technical Parameter

Work table: 810*810mm

Max. Cutting: 780*780mm

Cutting thickness: 0.3-12mm

Cutting parallelism: ≤±0.10mm/500mm

Cutting speed: 0--25m/min (could supply Yaskawa servo system, speed 0-70m/min)

Dimension: 1230*1300*1200mm

Power: 1.9kw (fan 1.5kw, X axis motor 0.3kw, Y axis motor 0.3kw, Z axis motor 0.2kw)

Voltage: 380V(fan)/220V(PC)/50HZ

Equipment configuration:

Stepping motor and drive (could supply Japan Yaskawa servo system)

Taiwan Guideway, ball screw rod, ensure accuracy and stability of equipment

Table with resin material, and the flatness is extremely high , and the self - milling treatment. Air suction device is attached to facilitate the upper and lower sheets, without scratching the glass.

Computer WINDOWS operation interface CAD graphics input, automatic cutting of various shapes of glass, easy to operate.

Function

SY-automatic glass cutting machine adopts step motor, driver and NC control system, equipped with imported cutter wheel, can realize all kinds of glass and ultra-thin glass straight, shaped, circular cutting. The machine adopts man-machine interface and can be cut by CAD drawing.

After-sales service and maintenance

In order to ensure the normal operation of the machine, our company will carry out complete and detailed training to the operator of the customer until fully master the operation.

Equipment warranty for one year (non-human factors) no charge for maintenance. Carry out repairs for many years.

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712