Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

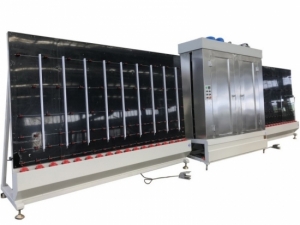

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

Item NO.:

SY-600-8Product Origin:

ShanghaiColor:

Steel blueShipping Port:

Shanghai/NanjingLead Time:

25 daysWarranty:

1 yearSize Range:

600*600mm -200*200mmProcessing Range:

Flat glassNo.1 Double side straight line grinding machine

The equipment is suitable for grinding flat glass, which is suitable for flat bottom rough grinding, fine grinding, and up and down chamfering can be completed at one time (our company can be equipped with glass cleaning equipment and automatic loading and unloading manipulators), using double linear guides, double rolling ball screws, Realize stable and accurate automatic opening and closing. The glass transmission is controlled by the frequency converter, the control software is designed by itself, and the touch screen is used for control.

Machine parameters:

Touch screen: Taiwan Delta

PLC: Taiwan Delta

Inverter: Taiwan Delta

Rotary encoder: Japan Omron

Switching power supply: Taiwan Delta

Motor: Anhui Yonghua special grinding head motor (3.0Kw & 2.2Kw & 1.1Kw)

Timing belt: 40mm wide

Timing pulley: aluminum alloy

Optical inspection switch: FC

Ball screw: Taiwan TBI (φ25mm)

Guide rail: Taiwan HIWIN (25mm)

Transmission motor: domestically equipped with reducer (1.5Kw)

Water pump: domestic submersible pump (1.1Kw)

Water tank: stainless steel

Drive shaft: chrome-plated optical axis (φ40mm)

Total weight: 1600Kg

Installed power: 17.5Kw

Power supply: 380V/50Hz

Grinding wheel diameter: φ130mm-φ150mm

Technical parameters (customizable):

Maximum processing width: 600mm

Minimum processing width: 200mm

Processing glass thickness: 2-12mm

Speed range: 2-10 m/min

Parallelism: ≤±0.25mm/m

Diagonal: ≤±0.45mm/m

No.2 Linear Rotary Table Model SY-2060

After receiving the glass from the No. 1 grinding machine, the rubber wheels are arranged at an angle to accelerate the movement. The glass walks against the reference edge, and then contacts the nylon material stop. The glass changes its direction by 90 degrees and enters the No. 2 Grinding machine.

Machine parameters:

Transmission shaft: chrome-plated optical axis (φ30mm)

Rubber wheel: polyurethane (φ90mm)

Sprocket chain: domestic

Transmission motor: domestically equipped with reducer (0.55Kw)

Inverter: Taiwan Delta

Optical inspection switch: FC

Technical parameters (customizable):

Total weight: 850Kg

Installed power: 0.55Kw

Power supply: 380V/50Hz

Processing range: 200*200-600*600mm

Rotation angle: 90°

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712