Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

Special glass edging machine is specially for cabinet door board, glass door board, display cabinet glass edging

Item NO.:

SY-1000-6Color:

Steel Blue or CustomizedLead Time:

25 daysWarranty:

1 YearSize Range:

50*50mm -2500*2500mmProcessing Range:

cabinet door board, glass door board, display cabinet glass edging

This glass edging machine is specially for cabinet door board, glass door board, display cabinet glass edging, Compared with the conventional grinding machine, the machining size is obviously reduced, could grinding minimum 50mm.For thickness above 2mm glass can be processed. Beyond the market of conventional edging machine can only process 3mm above the boundaries of glass. At the same time, the machine can achieve the accuracy of parallelism and diagonal.It is the best choice of door and window, optics, electronics, glass handicraft, glass and so on.

A. Main structure

SY-1000-6 horizontal glass linear edging machine is one of the series of high precision glass linear edging machines designed and manufactured according to the principle of bilateral edge grinder for the purpose of market demand.

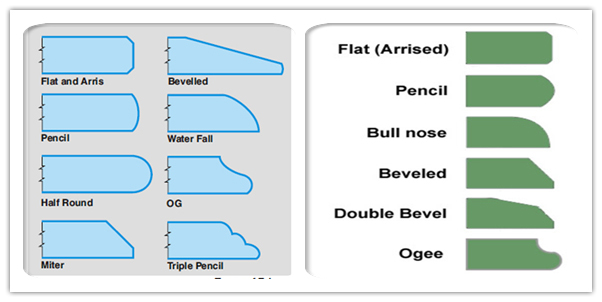

Grinding different size and thickness flat glass size for straight line rough grinding and fine grinding and two side angles chamfering. Total have 6 spindles: one diamond spindle, one resin spindle, one upper charfering and 2 polishing,under chamfering.

Can realize the 45 degree big bevel finish grinding of the upper chamfer, finish the polishing at one time. A rough and fine grinding of the bottom edge; a fine grinding of the lower chamfer. Mechanical stepless speed regulation, adjustable range, stable speed change, can change the feed speed in the grinding process, synchronous belt clamping and transmission thickness of 2-12mm glass for grinding.

B. Technical parameter

Max. Glass size 2500*2500 mm (could do customized)

Min. Glass size 50*50 mm (also could do 55mm need customized)

Grinding glass thickness 2-12mm

Speed: 0.5-4m/min

Workbench height: 750mm

Power: 8.9kw

Voltage: 380V/50hz (or customized)

Parallelism ≤0.20mm/m

Diagonal ≤0.40mm/m

Weight: 1800kgs

Dimension: 2800*1500*1650mm

C. Equipment configuration

Spindle motor: Xindongya Guangzhou

Transmission, switch on and off, lift motor: Shanghai Ruijin

Wire Rod: TBI taiwan

Guide rail: HIWIN taiwan

Transmission optical shaft: Wuxi chrome plated hard shaft

Other electrical devices: circuit breaker (Zhengtai); encoder (Omron); AC contactor (Siyan Technology)

Synchronous wheel: imported 2A12 aluminum alloy

Synchronous belt: Italian Babel seamless steel wire belt

Grinding wheel: domestic high-quality diamond wheel and Italy imported resin wheel.

Transfer wheel: PU rubber wheel

Related picture

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712