Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

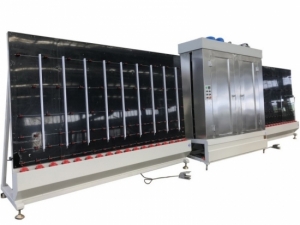

SY-1600 glass washing machine is suitable for washing and drying electrion glass, household electrical appliances glass, building glass and Optical glass.

Glass washing machine is horizontal structure, one section glass cleaning structure, beautiful appearance, cleaning and drying part of all stainless steel cover.

Item NO.:

SY-1600Color:

Steel Blue or CustomizedLead Time:

25 daysWarranty:

Float glassSize Range:

200-1600mm (Width)Processing Range:

1 Year

SY-1600 glass cutting machine is equipped with a stepless transmission, cleaning speed can be adjusted arbitrarily and adjust the transmission speed of glass according to the requirement of the process, to acheive the stepless speed. Equipment for dense drum drive design, large processing area. Put glass on feeding section, glass through feeding section, washing section, water absorption section, wind drying section and drying section, to arraive discharge section.

Washing part with gearand chain link, chain combined transmission and considerable number of clean brushes and water absorent sponges to ensure cleanliness. According to different glass thickness, brushes, sponges position could be moved up and down, after washing section, there is air knives to dry the water. Heating box with heating rod and fun motor to supply wind, the temperature controller can adjust the temperature of 20-100 ℃

A structure configuration:

a. GB square tube frame, cover is 1.2mmiron sheet spray.

b. The cleaning section and drying section are made of stainless stell shell

c. 4 pairs brushes (brush hair diameter is 0.15mm American DuPont nylon silk, could wash Low-e glass and ensure the glass surface no damage ), natural rubber material roller could ensure the cleaning effect.

d. The drive part is controlled by the variable frequency motor. It can adjust the cleaning speed.

e. 3 pairs water absorbent sponge roller, adpots imported PU material with high temperature resistance, acid and alkali resistant material, long service life.

f. Drying section 2 pairs of stainless steel air knives are configured to effectively ensure the air drying effect on the surface of glass after washing.

g. There is stainless steel heating box, temperature controller can adjust the temperature of oven, to ensure the glass dryness.

h. This machine is designed for a dense drum, with a large area of processing area, and the cleaning glass of circlulating water is completed once.

B Basic technical date:

a. Glass size washing range (width):200*200 — 1600mm

b. Glass thickness:3-19mm

c. Stainless stell heating pipe:9kw(1.5kw*6pcs),380v(drying baker)

d. Transmission system stepless transmission:0.75kw,380v(Stepless speed change)

e. Water pump::550w,380v

f. Gear brush motor:0.75kw,380v

g. High pressure positive blower:8KW

h. Total power:18.3KW

i. Weight:1000KG

j. Dimension:4500×1950×1000(mm)

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712