Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

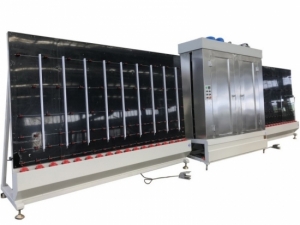

This production line is customized according to customer requirements. A total of 5 machines are composed. The composition of the machine is as follows: 1 SY-4028 double-turn single-station automatic loading machine. 2 SY-4028 automatic glass cutting machine. 3 Fully automatic horizontal breaking machine. 4 Fully automatic vertical breaking machine. 5 SY-800-2 washing machine;

Glass feed section-glass cleaning section-glass drying section-glass discharge section-assistant inspection section.

The automatic glass cutting machine is designed and manufactured according to the requirements of the buyer. The front and rear sections are connected to the glass chip taking manipulator, which is used to complete the automatic cutting and special-shaped process of cooktop panel glass.

This table is for glass transmission, the table size is customized according to customer's requirements.

This machine is a new generation of full automatic laminated glass cutting machine developed by our company in recent years. It has the characteristics of simple operation, high adaptability and high cutting accuracy.

The entire automated assembly line is fully automatic for the glass plate with a plate width of 1830 * 1220mm, a processed size of 454 * 404mm, and a thickness of 1.5-10mm --- cutting --- --- breaking --- delivery to the customer Own next equipment (height 900mm), realize unattended operation, and meet the production cycle of small pieces of glass to ≤12S / piece.

Production line composition:

SY-1813-U double flips single station full automatic sucker-type loading machine

SY-1813-C Full Automatic CNC Glass Cutting Machine

X-Break-Out Full-Automatic Breaking Machine

Y-Break-Out Full-Automatic Breaking Machine

Equipment detailed introduction:

SY-1813-U double flips single station full automatic sucker-type loading machine

1.1, mechanical configuration

Reverse sprocket chain: special high-precision reinforced transmission rubber wheel: imported PU material

Vacuum suction cup: Imported butadiene rubber material (double-adsorption structure) Transmission / turning motor: Domestic variable speed motor speed control

Vacuum pump: domestic-specific vacuum pump

1.2, electrical components

PLC controller: Taiwan Delta

Inverter: Taiwan Delta

Proximity switch: cable energy

Control cable: flexible shielded cable

AC contactor: CHINT

Pneumatic originals: The main originals are from Taiwan AirTAC

Positive and negative pressure sensor: Japan SMC

Touch screen: Taiwan Delta

1.3 Technical parameters

Minimum loading size: 1500 * 1200mm

Maximum loading size: 1830 * 1220mm

Loading thickness: 1.5-10mm Loading cycle: 40-60 seconds (adjustable)

Transmission speed: 0-40m / min (adjustable) Maximum suction pad depth: 600mm

Maximum loading load: 300KG Number of loading arms on one side: 3

Number of single-arm suckers: 3pcs

Upper flip arm: both sides

Loading station: single station

Installation power: 380V / 50HZ (special circumstances can be adjusted according to customer requirements)

Installation power: 8KW

Compressed air: 0.3Mpa-0.5Mpa

Vacuum pressure: -70- -90Kpa (adjustable according to glass thickness)

SY-1813-C Full Automatic CNC Glass Cutting Machine

2.1 Structure Introduction

Horizontal structure; rack and round guide drive; servo motor drive; X-Y-Z three-axis motion, motion control card control, computer operation.

2.2 Processing parameters

Maximum cutting size: 1830 * 1220mm Minimum size after cutting: 200 * 200mm

Cutting thickness range: 1.5-10mm (Cutter wheels of different thickness need to be replaced and the pressure is reset)

Straight parallelism: ≤ ± 0.2mm / m Diagonal accuracy: ≤ ± 0.45mm / m (The above accuracy is subject to the accuracy of the cutting line before the cymbal)

Cutting bridge speed: 0-120m / min. (Adjustable) Cutting bridge acceleration ≥3.0m / s²

The speed of the machine head is ≤160m / min, and the acceleration of the tool head is ≥6.0m / s²

The conveying speed of the belt is ≥40m / min, the positioning accuracy error of the cutting head is ≤ ± 0.15 mm

2.3 Power / Power

Installation power requirements: 380V / 50HZ

Equipment actual power: 8KW

Compressed air: 0.6PA

2.4 Mechanical configuration

Frame: square tube welding

Platen: Imported waterproof / fireproof plate (flatness of table surface ≤ ± 0.20mm / m)

Rack / rail: Japan KHK

Transmission belt / pulley: high quality domestic

Knife wheel / wheel clamp: Japan TOYO

2.5 Electrical configuration

Using Microsoft Windows interface, brand assembly computer

Motor: Three axes are selected from Japan's Yaskawa servo motor

Proximity switch: Yangming, Taiwan

Control card: American Galil motion control card

Main electrical parts: Zhengtai

Pneumatic proportional valve: Japan SMC

X-Break-Out Full Automatic Horizontal Separator

3.1 Product Features

This machine uses the upper straddle cutting line roller to hold, and the lower ejector mechanism. Up and down are pneumatically controlled. According to the collected data signals, the cut glass is cut off. The broken glass is transferred to the second section of the machine. After fully entering the second section, the side transfer rubber roller is lifted to transfer the glass to the longitudinal film machine.

3.2 Product configuration

Frame: National Standard Square Tube Welding

PLC: Taiwan Delta

Touch screen: Taiwan Delta

Transmission motor: Taiwan Delta Servo

Cylinder: domestic adjustable cylinder

Pressure wheel: Homemade POM wheel

Transmission timing belt: high-quality domestic

Holding: Polyurethane rubber wheel

3.3 Processing parameters

Original film processing range: ≤1830 * 1220mm

After the cymbal range: 456 * 404mm (can be designed according to the requirements of the customer)

Equipment installation power: 3kw

Beat: meet the entire line of beats

Y-Break-Out automatic longitudinal film machine

4.1 Product Features

This machine uses the upper straddle cutting line roller to hold, and the lower ejector mechanism. Up and down are pneumatically controlled. According to the collected data signals, the cut glass is cut off. The broken glass is transferred to the second section of the machine. After fully entering the second section, the side transfer rubber roller is lifted to transfer the glass to the next machine.

4.2 Product configuration

Frame: National Standard Square Tube Welding

PLC: Taiwan Delta

Touch screen: Taiwan Delta

Transmission motor: Taiwan Delta Servo

Cylinder: domestic adjustable cylinder

Pressure wheel: Homemade POM wheel

Transmission timing belt: high-quality domestic

Holding: Polyurethane rubber wheel

4.3 Processing parameters

Original film processing range: ≤500 * 1220mm

After the cymbal range: 456 * 404mm (designed according to the requirements of the buyer)

Equipment installation power: 3kw

Beat: meet the entire line of beats

Anhui Ruilong Glass Machinery Co., Ltd.

Email address : info@ahrlbljx.com

Phone : +8613063758190

Add:No.9 East of Shengli Road, Longzihu District

Copyright © Anhui Ruilong Glass Machinery Co., Ltd.

online service

online service +86 15655238712

+86 15655238712 info@ahrlbljx.com

info@ahrlbljx.com +86 15655238712

+86 15655238712